Technical Ability

|

One of the reasons our clients keep returning to work with Associated Rewinds is our engineering abilities that enable us to solve issues with problematic motors.

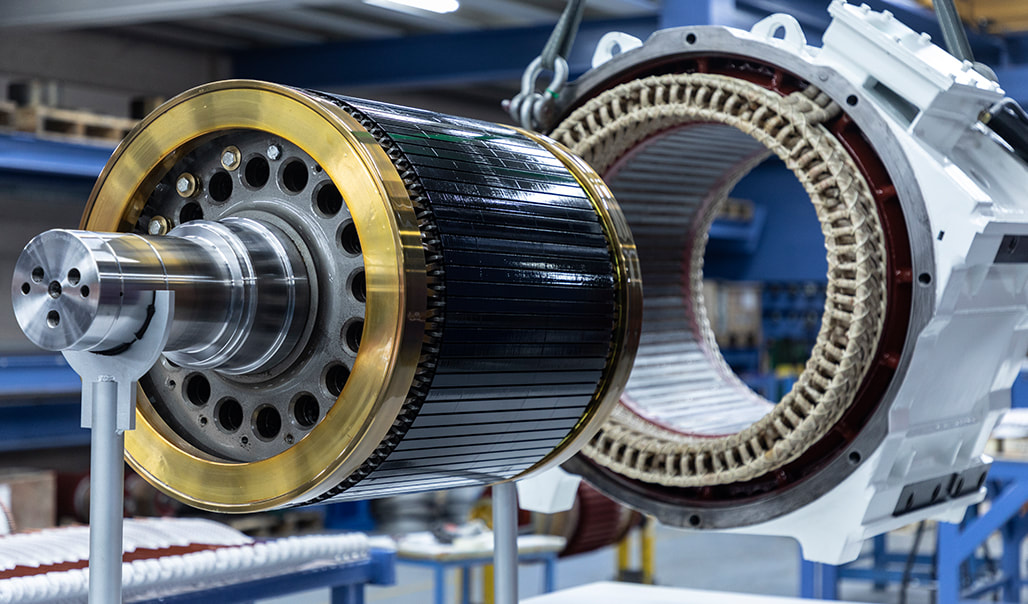

Another reason is the quality of our work which is driven by the company ethos of engineering excellence that we have at the core of our business. This technical knowledge enables us to re-design parts when needed, as well as manufacture our own: ➧ New Armatures ➧ New Rotors ➧ New Shafts ➧ New End Bells ➧ New Field & Interpole Coils ➧ New Slingers ➧ Upgraded Stator Rewinds |

Increase Power Output

|

Another option we have provided to clients is to increase the power output of their motors from a total of 5.6MW to 7.0MW.

This has enabled our clients to increase efficiencies on track by hauling more wagons behind each train, maintaining uphill speed, reducing track usage costs when they run fewer trains and lowering staffing costs. A train operator can save a lot of money by upgrading an existing motor, instead of purchasing a new one from the OEM. |

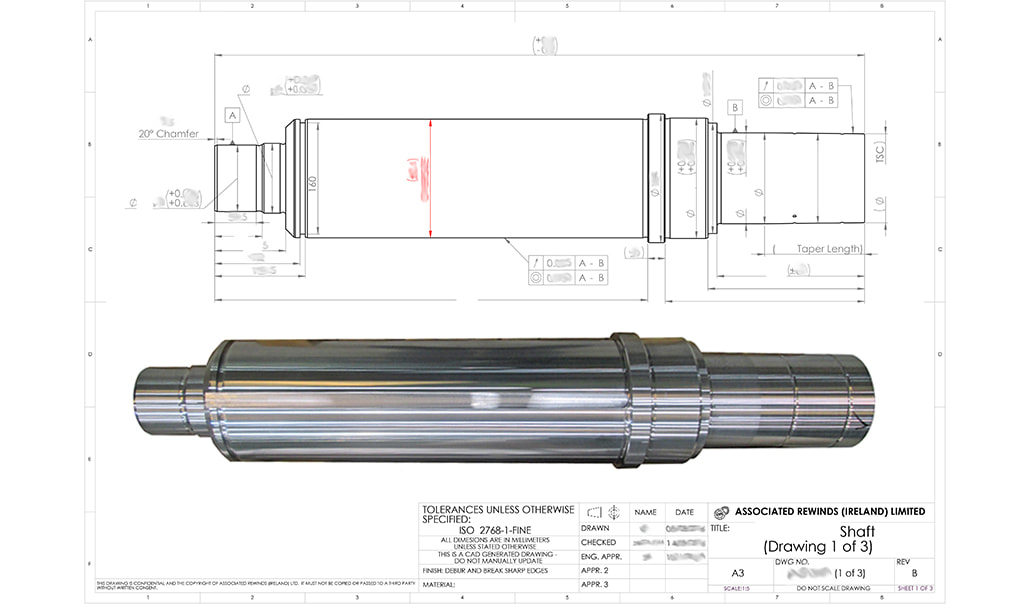

Reverse Engineering

|

An issue that we have seen several clients suffer from is where they require substantial repairs to be carried out on a type of motor they purchased from an OEM or as part of a locomotive or tram set, however the OEM has not, or will not deliver a detailed set of drawings for the motor to this client.

There are several highly qualified engineers working at Associated Rewinds who have proven their technical abilities by reverse engineering the manufacture of a motor without having access to any OEM drawings. Our engineers have made their own CAD drawings, which have been approved by the client and the motors manufactured. |